Status

1. Facilities

| Design Equipment | Analyzing Equipment | Testing Machine |

|---|---|---|

| CATIA : 19 units | Ls-Dyna | S / BELT ANCHORAGE tester |

| AUTOCAD : 9 units | Hyper Works | SEAT Strength Tester |

| Unigraphics : 3 units | POWER Durability Tester | |

| Others : 3 units |

2. Ongoing tasks

3. Mid- to long-term planning

We possess the product design and analysis technologies using systems like CATIA V4,V5 , UG NXIII, HYPER MESH, and LS-DYNA, develop and assess R&D projects.

Based on much manufacturing experience and independent facility manufacturing technologies, we support AUTO WELDING SYSTEM , the specialized field of research.

| No. | Classification | Facility Name | Spec. |

|---|---|---|---|

| NO.01 | Design equipment | CATIA | V4 |

| NO.02 | CATIA | V5 | |

| NO.03 | AutoCAD | 2000 | |

| NO.04 | U.G | ||

| NO.05 | HIRIX | ||

| NO.06 | Analysis equipment | Ls-Dyna | |

| NO.07 | Hyper Works | ||

| NO.08 | Manufacturing equipment | Milling | 6th machine |

| NO.09 | 5th machine | ||

| NO.10 | complex 3rd machine | ||

| NO.11 | complex 2rd machine | ||

| NO.12 | Vertical | ||

| NO.13 | General lathe | 1300mm | |

| NO.14 | Conda | ||

| NO.15 | Drill machine | ||

| NO.16 | Mag drill | ||

| NO.17 | Measuring equipment | Vernier calipers | 600mm etc |

| NO.18 | Height gauge | 600mm etc | |

| NO.19 | Micrometer | 0~25mm etc | |

| NO.20 | Dial gauge | 0.01 | |

| NO.21 | Indicator | 0.01 |

We are realizing competitive products by securing quality in the early stage and design technologies of seat frame using the various kinds of testing machines.

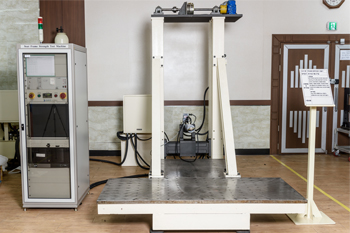

FRAME strength tester

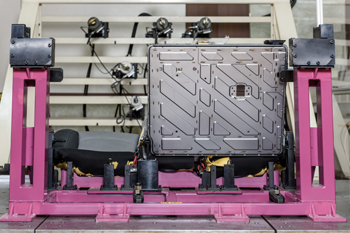

POWER SEAT strength tester

SEAT BELT ANCHOR Tester

SWIVEL Interval tester

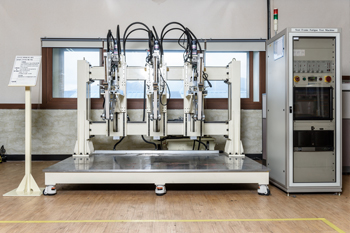

Repeated load (fatigue) durability tester

Soundproof room (exterior)

Soundproof room (inside)

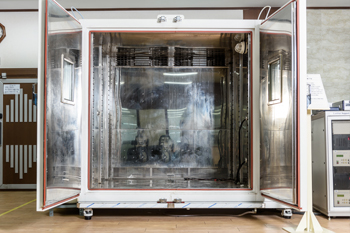

Constant temperature and humidity chamber (outside)

Constant temperature and humidity chamber (inside)

Test room view

Test room view